- Introduction:

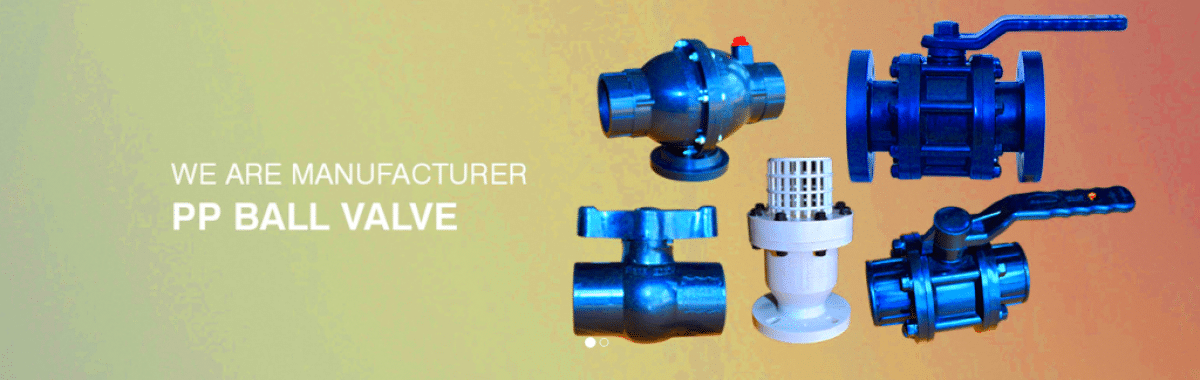

We, Gokul Poly Valves is an Ahmedabad based assembling organization that produces pipes, as MDPE pipe. With the contribution of very good quality innovation, current hardware and high level apparatuses in the entirety of our cycles, we are well-known MDPE Pipe Manufacturer that are the most appropriate for transportation of gas as well concerning water.

These lines are made with Medium Thickness Poly Ethylene under the direction of gifted experts according to the set business standards. MDPE Pipes are esteemed for their traits like erosion and break safe, intense and adaptable makes Polyethylene channelling frameworks. The offered pipes are severely tried on a few boundaries under the direction of gifted group of value regulators.

- MDPE Pipe:

MDPE pipe which is short for Medium Thickness Polyethylene Line is a less dense rendition of HDPE pipes. This lines are utilized in both home-grown and modern foundations which require MDPE fittings for cold mains. Regardless of being a piece less in each division than HDPE pipes, MDPE makes for a phenomenal substitute due to its strength, simplicity to establishment and capacity to convey gas at all tension levels. It ought to be noticed that MDPE is a sort of material which isn’t only utilized for making pipes, it is likewise utilized for making shrink films, sacks, convey packs and so on.

These lines supply water from repositories to various geographic regions. The water supply associations or house administration associations can be isolated into classes – stand posts, private associations and non-home-grown associations. MDPE pipes guarantee that water is provided to this large number of zones immediately. These parts incorporate water meters, pipes, valves, capacity tanks, fittings, water treatment plants, etc.

Benefits:

- Light weight, Adaptable and sturdy

- Crack safe

- Robust development with high effect strength

- Suitable for cold and waste water conveyance framework.

- Low contact misfortunes because of amazing smooth inside surface.

Also, these lines are made with Medium Thickness Poly Ethylene under the direction of talented experts according to the set business standards. MDPE Lines are esteemed for their characteristics like erosion and break safe, intense and adaptable makes Polyethylene channelling frameworks. The offered pipes are rigidly tried on a few boundaries under the direction of gifted group of value regulators.

Features:

- Complicatedly wrapped up

- Simple fitting

- Exceptionally tough